Pipe By Cloud

This is a post about the new tool PipeByCloud included in the new release 1.22 of cloud2model.

PipeByCloud is a productivity tool for fast creation of pipes with just two clicks on the apparent visible side of the pipe in the point cloud. The automatic detection of the pipe diameter and axis is near instantaneous allowing a very fast and practical workflow in MEP scan2BIM scenarios. Additionally, the tool gives feedback about the level of confidence of the automatic detection and it has several options for further geometrical regularization.

PipeByCloud has been specifically developed for typical point cloud representation of pipes in buildings, that normally are close to ceilings or walls, resulting in a limited recorded area (actual part of the cylindrical surface of the pipe that is visible in the point cloud) and frequent noise and reflection artifacts.

This new tool of cloud2model is a high value asset for creating accurate MEP models from point clouds.

Before using the tool.

For an efficient use of the tool we will prepare in advance a 3D view with a section box of the area containing the visible pipes in the point cloud.

The minimum view extension the better. If we have several rooms of delimited areas with pipes, it is better to work individually with each area or room.

When pointing in the screen to the apparent visible side of the pipe in the point cloud, it would help if we don’t have other visible objects visible on front of the pipes. These objects can block the actual visibility of the side of the pipe recorded in the point cloud. For this reason it is recommended to limit the depth of the 3D view to the minimum needed.

For near horizontal pipes close the ceiling, the section box could be like a horizontal slice with the minimum vertical depth to see the pipes recorded in the point cloud.

For vertical pipes close to a wall, the section box could be like a vertical slice with the minimum horizontal depth to see the pipes recorded in the point cloud.

Keep in mind that the tool can only be used with 3D views with section box. If you have already a cropped 2D view floor plan/RCP/section with the area to study, you can use the cloud2model tool 3D<>2D to automatically get a 3D view with the a section box matching the 2D view (or the other way around). Additionally, the tool DynamicView can help greatly to adjust the 3D view section box.

Options.

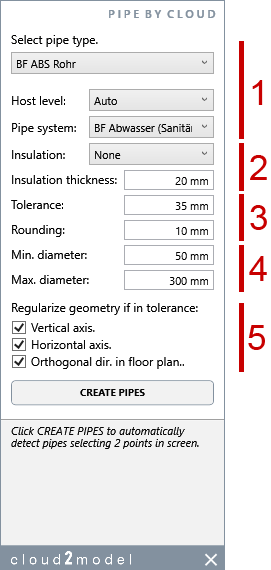

The new tool will open a separate window with all the available settings.

1 Main options for the new pipes created.

Pipe type to use from the pipe types of the current project.

Host level. We have three auto options or we can directly select any current floor level. The auto options are:

“Auto”, closes level to the axis middle point.

“Auto lower”, closest lower level to the axis middle point.

“Auto upper”, closest upper level to the axis middle point.

Pipe system to assign for the new created pipes.

2 Insulation options.

We can set if we want to consider insulation. In this case, the detected diameter will be assumed as the outer global diameter of the pipe + insulation. We can select from the types of insulations defined in the project.

The insulation thikness to use if we have set any kind of insulation.

3 Geometrical tolerance and rounding.

Tolerance to consider for the geometrical regularization (see bellow)

Rounding of the exact diameter detected.

4 Diameter range for automatic detection

Minimum diameter to be detected.

Maximum diameter to be detected.

5 Geometrical regularization

If the axis is near vertical, force to be perfectly vertical if in tolerance.

If the axis is near contained in a horizontal plane, force to be perfectly horizonal if in tolerance.

If the axis is close to follow in floor plan the main orthogonal directions of the project, force perfectly orthogonal directions in floor plan.

Creating new pipes.

After preparing the view and setting the options as explained above, we can start to automatically detect pipes with “CREATE PIPES”.

We will click two points in the apparent visible surface of the pipe and a new pipe will be automatically created, with automatic detection of the diameter and axis.

We can continue clicking two points and creating new pipes until pressing the Esc. key at any moment to stop the command.

Each new pipe created with appear as a separate command in the undo command list. We can undo the last(s) pipe(s) created without cancelling all the pipes created in the command.

The feedback area of the tool window gives information about the current step in the process and about the created pipe:

Level of confidence of the automatic detection (high, medium, low).

Exact diameter detected.

Actual rounded diameter of the new pipe.

Any geometrical regularization.

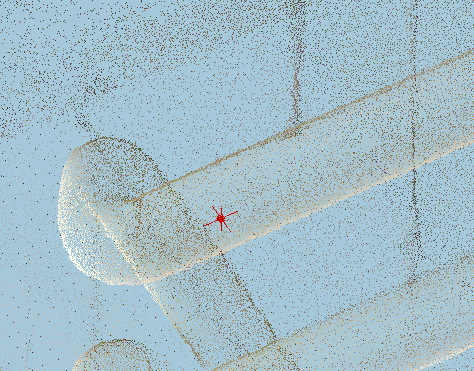

Additionally, we have some visual feedback in the 3D view.

A small red cross in each of the two point clicked in the screen. This allows visual feedback about the actual point recognised in the apparent visible surface of the pipe in the point cloud.

After the new pipe is created, a big cross in the pipe ends with a different color depending of the level of confidence: green for high, orange for medium and red for low. This complements the text info in the feedback area of the tool window.

The visual feedback in the 3D view is temporal and it will disappear when we stop the command pressing escape.

If after selecting the 2 points, no pipe is automatically detected, we will get a notification error in the feedback area.

.

Best workflows in using the tool.

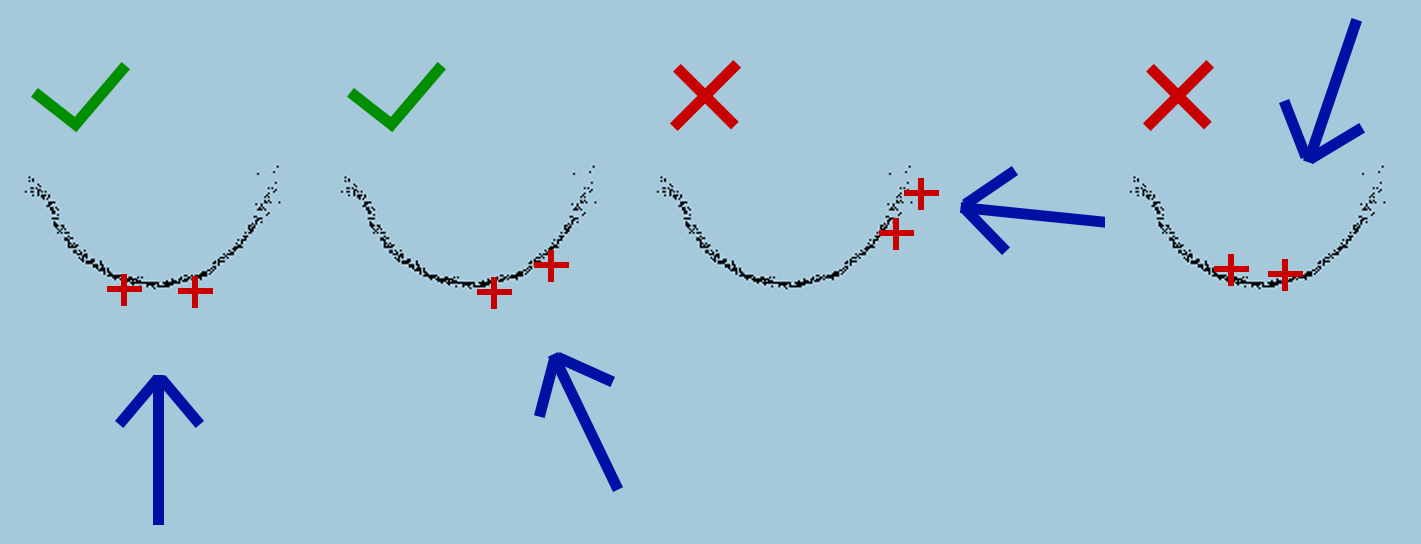

Because the pipes will be normally close to a surface, like a ceiling or a wall, the surface recorded by the point cloud will by partial, tipically 180° or less.

The pipe surface must be visible from the exterior or convex side. Ideally the view orientation will be parallel to the normal direction in the middle part of the surface (first from the left).

The view can be a bit tilted from the ideal orientation (second from the left).

It is important to avoid that the view orientation is too tilted, or close to be perpendicular from the ideal orientation (second from the right).

Never use a point of view that the pipe surface is visible from inside or concave side (first from the right).

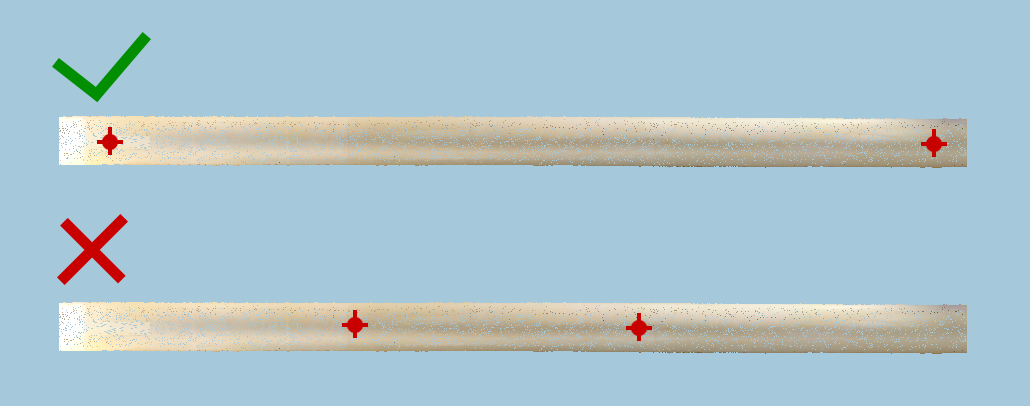

When clicking the two points, the more close to the imaginary center line of the visible surface, the better.

It is no needed that the two points are perfectly in the center, but it is is better to avoid points too close to the sides of the visible surface.

In order to easily click the points in the central part of the visible surface, it would be helpful if we orientate the 3d view in a way that the visible surface of the pipe is more or less frontal to the direction of the view.

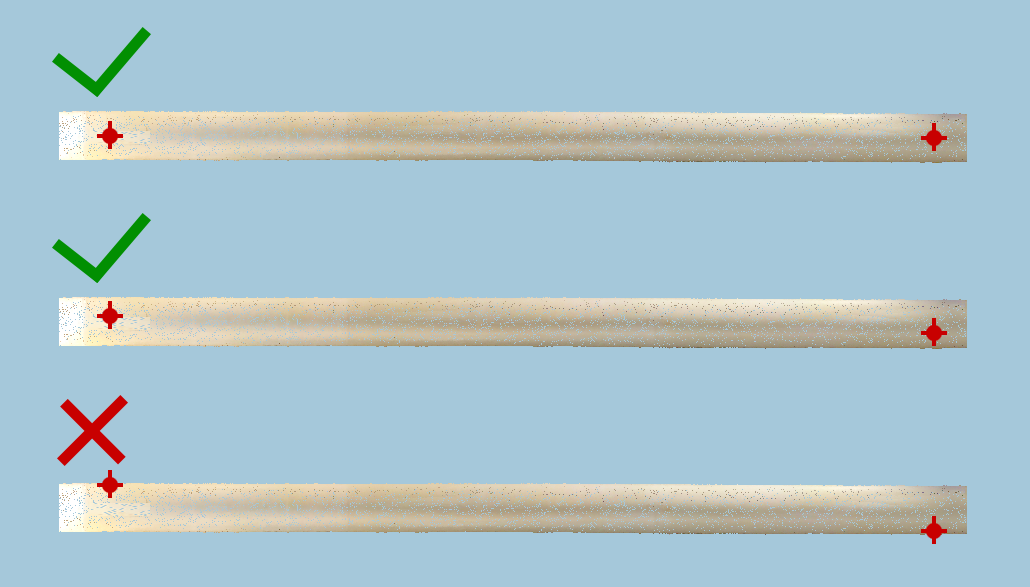

Ideally, the direction of the point of view will be parallel to the normal direction of central part of the visible surface of the pipe, like in the upper image.

If the view is a bit tilted (middle image), it will be ok. But we must avoid point of view orientations like in the lower image.

When a new pipe is created, its extension will follow the original two points clicked. Although is very easy in Revit to extend the pipe afterwards, we must always remember that the geometry regularization check the actual pipe length related to the original 2 points. This means, that maybe it can be regularised being in tolerance with the length by the original 2 points, but after it is extended it could be not in tolerance anymore.

If we have the regularization settings on, it is convenient to click the points covering most of the actual length of the pipe.

In general the most problematic point clouds artifacts in pipes are reflections. If in the visible pipe surface we see big differences in the apparent brightness, it is recommended to avoid to click points in the most bright (near white) areas.

The maximum diameter setting drive the size of the area to analyse in the diameter detection. The smaller the value, the fastest the automatic detection will be. A bigger value that needed will not affect the quality of the result, but it can extend unnecessarily the processing times.

The minimum diameter setting may have an influence in the quality of the result. Very small values may result in wrong diameter detections when used for pipes with a lot bigger diameter. It is strongly recommended to set the minimum diameter as big as possible. And only use very small values when are trying to the detect pipes in that range size.

The level of confidence feedback is set depending on:

Similarity of the diameter detected for both points.

Internal consistency in the automatic detection for each point.

If the level of confidence is other than high, it is mostly because too much difference in the diameter measured in each point. A detection with medium level will probably be ok, but with low level it is recommended to check the result.

Checking the result.

The coud2models tools CrossSection and LongSection have been updated in order that they can be used with pipes.

With CrossSection we will click a pipe, with automatic creation of the cross section in the point clicked.

With LongSection we will click a pipe, with automatic creation of a longitudinal section of the whole extension of the pipe clicked.

Please take into account the diameter rounding value and the geometry regularization can result in some deviation between the precise axis and diameters detected and the actual pipe created.